في عالم التصنيع والإلكترونيات والأعمال اليدوية، يُعد جهاز التلحيم النقطي (Spot Welder) من أبرز الأدوات التي تجمع بين الدقة والسرعة والفعالية. هذه المراجعة تتناول فحص دقيق لجهاز تلحيم نقطي من علي اكسبرس بمسمى تجاري 80 Gears Spot Welder.

نظرة عامة على المنتج

مواصفات الجهاز

- جهاز لحام نقطي محمول، يعمل بدون الحاجة لتوصيل مباشر بالكهرباء (يعتمد على بطارية داخلية).

- مخصص لتلحيم شرائح النيكل المستخدم في بطاريات الليثيوم مثل 18650.

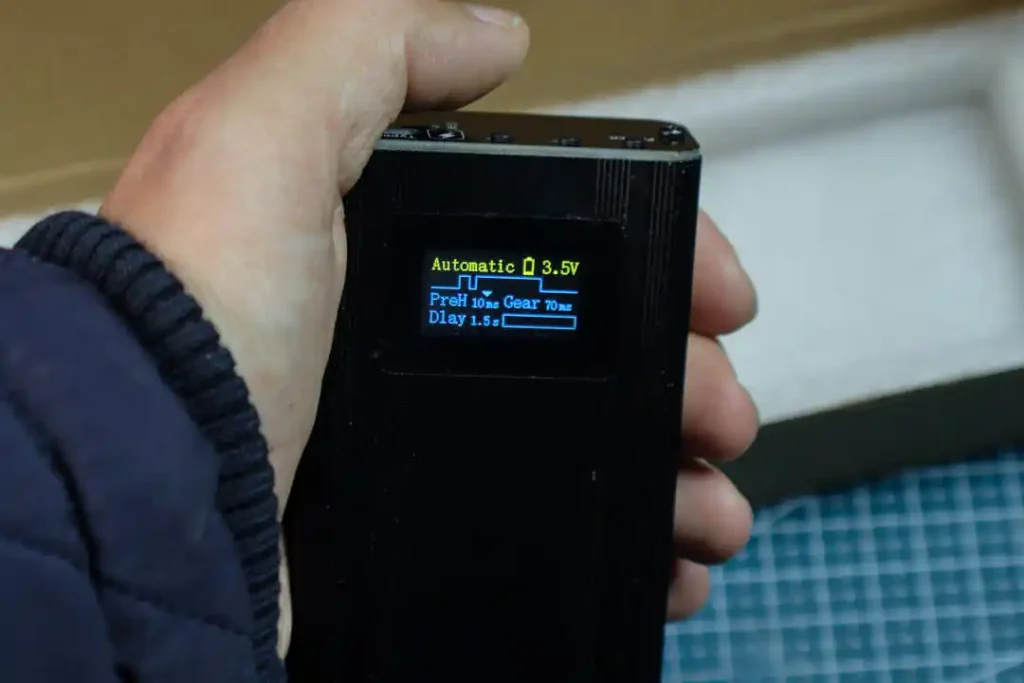

- إعدادات قوة قابلة للتعديل عبر زر (Gear).

- شاشة LCD توضح حالة الجهاز والشحن والجهد الزمني للنبضة.

- يُرفق مع الجهاز شريط نيكل إضافي.

التطبيقات المستهدفة

- توصيل شرائح النيكل على بطاريات الليثيوم (لأغراض مشاريع DIY، مثل بناء بطاريات الباوربانك أو دراجات كهربائية صغيرة).

- مناسبة أيضًا لحام المعادن الخفيفة.

كيفية عمل الجهاز: الأساسيات العلمية

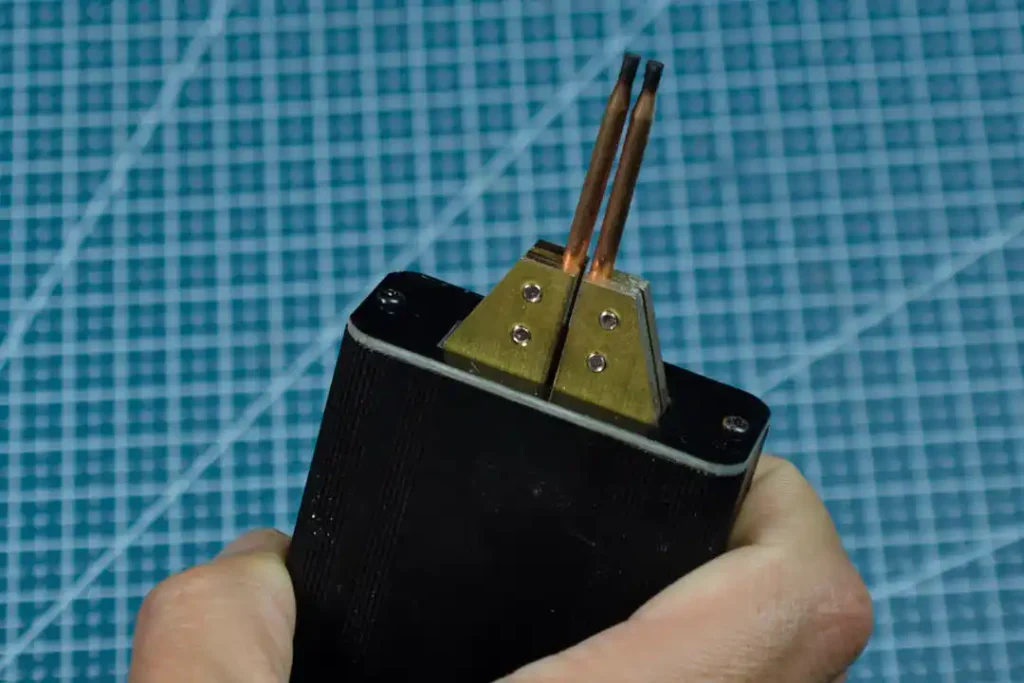

- مبدأ اللحام النقطي يعتمد على مرور تيار كهربائي عالٍ لفترة زمنية قصيرة عبر قطبين يضغطان على سطحين معدنيين، فينتج حرارة تذيب المعدن محليًا ويشكّل نقطة لحام قوية .

- الجهاز المحمول يستخدم بطارية ليثيوم-أيون قوية توفر تيارًا كافيًا لإنشاء هذه النقطة بدقة .

- التحكم بالوقت (ms) وقوة الضغط ضروري للحصول على نتائج متسقة دون حرق أو إضعاف اللحام.

الأداء العملي

إعدادات اللحام

- يُفضّل إجراء تجارب أولية على بطارية مهملة أو قطعة معدنية قبل الاستخدام الفعلي.

- إعداد “Gear 70” قد يكون قويًا للحام 0.15 مم، لكن المستخدمين وجدوا أن قيم منخفضة (مثل Gear 4‑30 ms) كافية وأكثر أمانًا .

- الفرق بين الوضع التلقائي والوضع اليدوي يكمن في دقة التحكم؛ التلقائي يسهل الاستخدام، واليدوي يعطي حرية ضبط أفضل.

استمرارية الأداء وعمر البطارية

- بعد 60–100 لحام من البطارية، تحتاج لإعادة شحن الجهاز (حسب تجربتي الشخصية) .

- الشحن الكامل يستغرق عدة ساعات، مما يعني ضرورة وجود بطارية احتياطية للعمل بشكل متواصل.

جودة اللحامات وموثوقية النتائج

- جديرة بتوصيل شرائح النيكل بدقة وقوة، خاصة مع الاستخدام الصحيح وتنظيف الأقطاب بانتظام .

- بعض المستخدمين واجهوا نفورًا في التوصيل عندما لا تُطبق القوة المناسبة أو تكون الأقطاب متسخة أو عندما يُستخدم إعداد قوي جدًا، مما أدى إلى إتلاف البطارية.

ضبط الزاوية والضغط

- توجيه الجهاز بزاوية 45° أثناء اللحام يعزز الاتصال والتغلغل، خاصة مع أسطح الأنود السميك .

- الحفاظ على نظافة الأقطاب مهم جدًا للحصول على لحام نظيف دون شوائب كهربائية.

الاستخدام الأمثل: نصائح عملية

التحكم في القوة والوقت

- البدء بوقت قصير (4-10 ms) وضبط القوة تدريجيًا حتى ظهور لحام متجانس بدون تفحم.

- إذا ظهرت شرارات كثيرة أو حدة، خفف الإعداد فورًا.

الزاوية المناسبة

- توجيه الجهاز بزاوية 45° يعزز ضغط الأقطاب على سطح البطارية/النيكل.

الحفاظ على البطارية الحيوية

- بعد إجراء عدد من اللحامات، حاول تخفيض شحن البطارية إلى 3.80–3.85 V للحفاظ على صحة البطارية الطويلة .

- بعض الأجهزة تدعم شحن USB لإنزال مستوى الشحن عن طريق تفريغ البطارية إلى 3.8 V، وهذا ميزة عملية لتخزين الأطول.

التنظيف الدوري

يجب تنظيف الاقطاب بعد كل استخدام، لأنها سريعة الاتساخ وعدم تنظيفها قد يؤثر بالسلب على النتيجة النهائية.

المزايا والعيوب

| المزايا | العيوب |

|---|---|

| • لا يحتاج لتوصيل كهربائي مباشر، استخدمه بكل حرية في أي مكان. | • عمر بطارية محدود، يحتاج شحن متكرر بعد ~60-100 لحام. |

| • قدرة لحام جيدة على شرائح النيكل 0.10–0.15 مم (تخصيص حسب الإعداد) | • الأقطاب قد تنسخ بسرعة وتحتاج تنظيف أو تبديل مستمر. |

| • دقة عالية، مناسبة للعمل على البطاريات الدقيقة | • احتمالية إتلاف البطارية عند الإعدادات الخاطئة أو تخطي نقاط الضغط. |

| • متنوعة الاستخدامات للمشاريع اليدوية وصيانة البطاريات | • عدم توفر وثائق رسمية باللغة العربية/الإنجليزية في إعلان المنتج. |

الصيانة والملحقات اللازمة

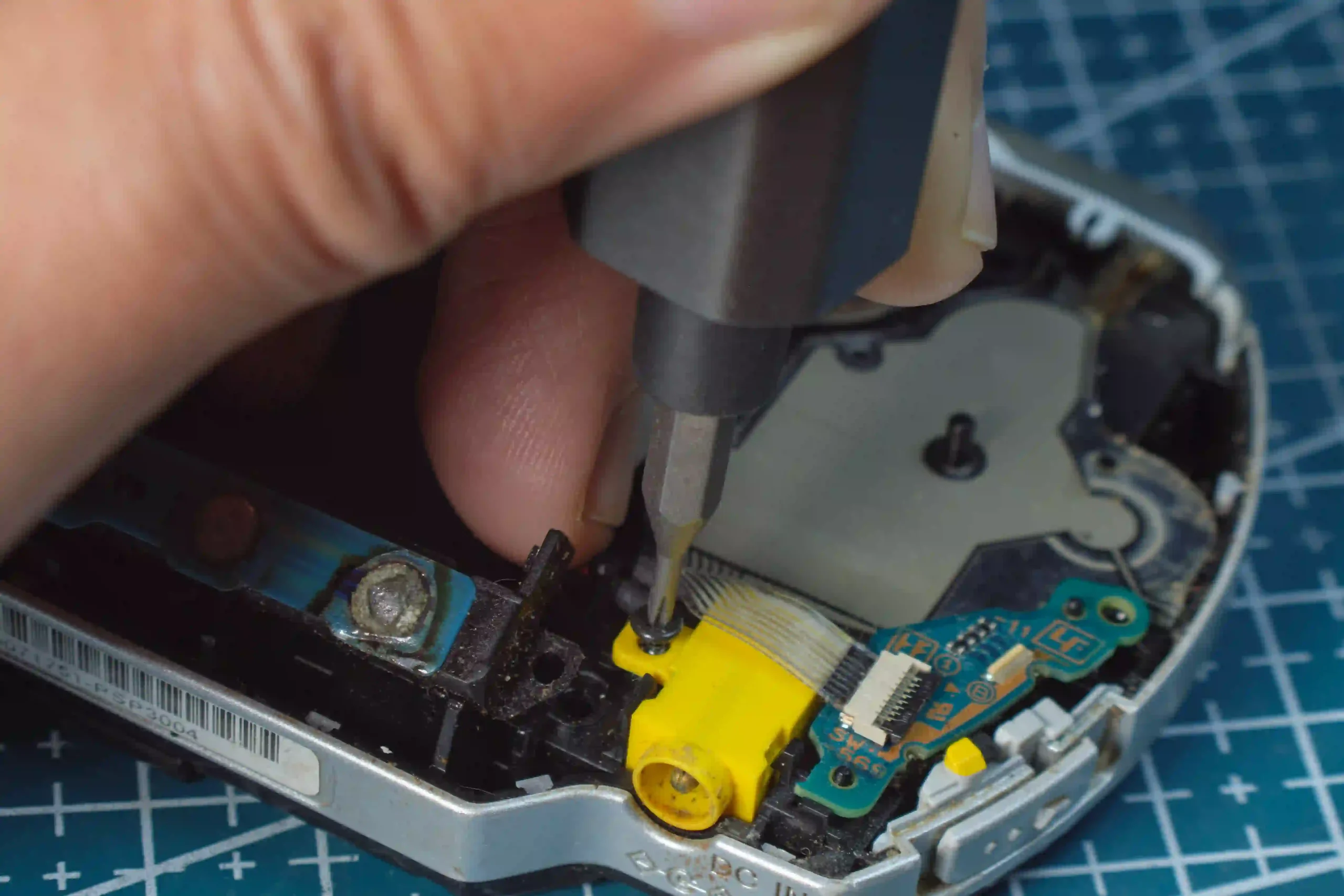

الأقطاب الكهربائية

- استبدل القطبان عند بروز احتراق أو تغير في الشكل لضمان ثبات الشدة والنقل الحراري.

البطارية الداخلية

- حافظ على شحن بين 30–80% أثناء تخزين الجهاز، تفادي الشحن الكامل لفترات طويلة للحفاظ على عمر البطارية.

الأداة المرفقة للتنظيف (احيانا)

- استخدمها للحفاظ على التلامس الكهربائي المثالي بين القطب والجسم المعدني، نظف بقايا المعدن الاحتراق دورياً.

قيمته مقابل السعر

- تتراوح أسعار أجهزة مشابهة على AliExpress بين 50–80 $، وهو سعر اقتصادي مقارنة بالأجهزة ثنائية الذراع أو المحطات الثقيلة.

- الجهاز يعتبر استثمارًا جيدًا للبداية، لكن للمشاريع الكبيرة والتركيبات الاحترافية، ينصح بالانتقال إلى DX10 أو الأجهزة ذات القدرة الأكبر.

- للحصول على نتائج عالية الجودة لمشروعات مثل بطاريات السيارات أو دراجات كهربائية، يمكن اقتناء بطارية أكبر أو جهاز أكثر قوة.

الخلاصة

يُعد جهاز التلحيم النقطي المحمول 80 Gears Spot Welder خيارًا ممتازًا للمبتدئين والمحترفين الهواة الذين ينفذون مشاريع لحام شرائح النيكل مثل بطاريات 18650 أو صناديق بطاريات DIY. يوفر الجهاز دقة وحرية حركة دون الحاجة للكهرباء الثابتة، ويتميز بسهولة الاستخدام. ومع ذلك، يجب الانتباه لضبط الإعدادات بشكل دقيق والتنظيف المستمر، وكذلك الاعتماد على أجهزة ذات سعة بطارية أكبر أو مقاومات محسنة في المشاريع الكبيرة.

توصياتنا:

- ابدأ بتجارب على قطع غير مهمة لضبط الإعدادات.

- استخدم إعدادات زمنية منخفضة (4–30 ms) لتفادي الأضرار.

- حسّن جودة اللحام بتنظيف منتظم للقطاب وضبط الزاوية والضغط.

- راقب صحة البطارية بتفريغ مناسب وتخزين صحيح.